Studio Eero Aarnio products are manufactured from start to finish at Melaja Oy's factory in Riihimäki, Southern Finland. The production process is versatile and a large part of the work steps are carried out by the skillful hands of our professional plastic molders and the artisan work of the finishing and assembly team.

Design interior lighting creates not only beautiful light, but also work and vitality for all stages of the production chain. In addition to lighting, we manufacture sympathetic interior objects that are often inspired by the animal world - Aarnion's Ponies , Dinos and Wuff dogs delight design lovers of all ages around the world.

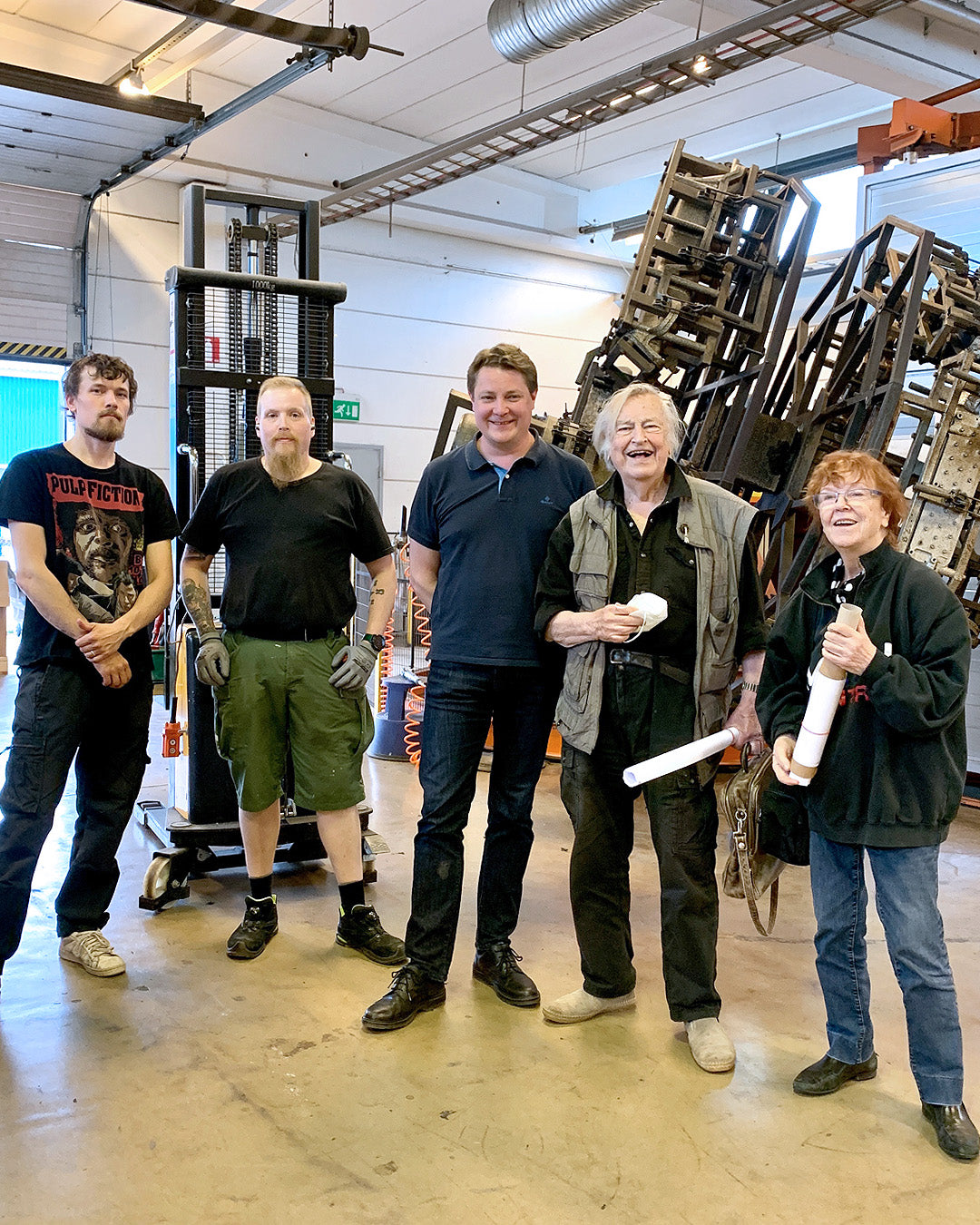

Everything starts from professor Eero Aarnio's designs. Aarnio knows the manufacturing process, and the designer's playful and innovative style is reflected in every product. Our lamps are both cheerful works of art and durable objects that, in daily use, bring joy and aesthetics to your home or office. All products in the collection have been awarded the Design from Finland label in recognition of Finnish design.

An uncomplicated dialogue during the design process guarantees that all aspects have been taken into account by the time of production and that the product is suitable for industrial manufacturing. The original idea is sometimes implemented as it is, sometimes small changes are made in order to ensure the technical implementation and usability in the best possible way. Not only the visual appearance of the product, but also its manufacturing method, safety, maintainability, and features to be considered during transportation are reviewed before the plastic machine can rotate with a brand new mold on board.

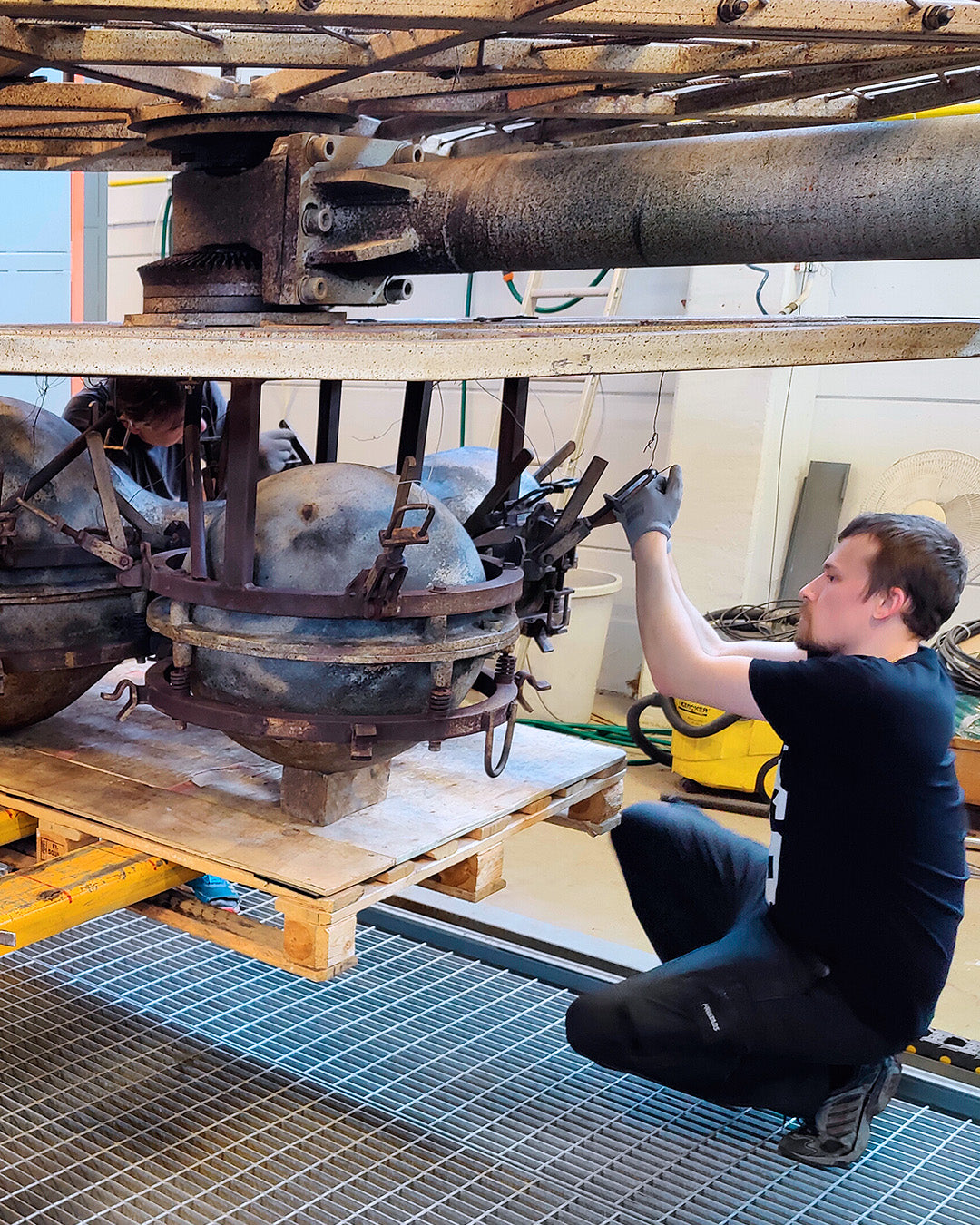

The rotational molding technology we use requires strength and precision from the operators of the plastic machine. Durable polyethylene plastic is dosed to the nearest gram into aluminum molds, after which it melts into its shape inside the rotating molds in a hot oven. In the production of colored products, the material is tinted before casting - the white plastic gets a shade picked from the happy world of Aarnio, and the final product retains its color both in hot and cold weather.

After cooling the molds are removed and the shade gets its final size and shape as the material cools. After this, the lamp moves to the finishing department, where everything is done by hand. The seam points created by the molds are finished, and quality control ensures that not a single particle of dust has gotten into the mold during the filling phase.

The electrical parts of the lamps are assembled from high-quality components, after which the shade is checked again while illuminated. Each individual product is packed carefully so that the lamp arrives undamaged to a happy customer. These light and durable design lamps are easy to transport, and our logistics partner will ensure that they are shipped undamaged and quickly.